The AZEK Company

FULL-CIRCLE™: AZEK Disrupts PVC Recycling by Revolutionizing Takeback

According to the EPA, the United States generated 600 million tons of construction and demolition debris in 2018. That’s 600 million tons of materials that are not repurposed and recycled as inputs for production of new products and instead lost to the landfill. In fact, one estimate says that by 2025, annual construction waste is expected to reach 2.2 billion tons globally. When your mission is to revolutionize outdoor living to create a more sustainable future, your goals must reflect that to show intent and ambition. So in 2021, The AZEK Company (AZEK) took the next big step in its sustainability journey: It pledged that it would recycle 1 billion pounds of materials annually by the end of 2026.

For AZEK, the industry leading manufacturer of beautiful, low-maintenance, and environmentally sustainable building products, with a focus on decking, outdoor living, and home exteriors, this pledge is perfectly in line with how they approach sustainability: as a circular journey that drives innovation, inclusivity, sustainability, business relationships and execution along the way. Announced on the heels of launching its first state-of-the-art polyethylene recycling plant along with its acquisition of leading polyvinyl chloride (PVC) recycler, Return Polymers, CEO Jesse Singh believes the pledge – and the FULL- CIRCLE™ PVC Recycling program – is emblematic of how the company looks at sustainability, as a full circle. “Our financial and sustainability goals are inextricably linked: Our business drives our approach to sustainability and our sustainability initiatives drive our business,” he says.

Getting started…with scrap

AZEK began its recycling journey in 2018, with an initial development of recycled material formulations and investments to upgrade manufacturing lines. In order to be able to accelerate its use of recycled material, AZEK first had to figure out how to source and collect all that scrap. The challenge was not in using it, but in sourcing it. The company’s strategy that focuses on sourcing, collecting and recycling three primary materials for recycling back into its manufacturing line: polyethylene, polyvinyl chloride (PVC) and wood flour. Sourcing recycled polyethylene and recycled wood flour had more established networks, while PVC proved to be modestly more challenging. One source for recycled PVC that AZEK was looking to explore was the scrap and waste generated from PVC-based building materials used in new construction and remodeling projects that would otherwise end up in landfills. With a diverse base of customers including distributors, dealers, contractors, and lumber yards across the United States, AZEK had multiple points of potential PVC collection but zero infrastructure at the state or municipality levels to tap into.

AZEK calls the strategy FULL-CIRCLE™

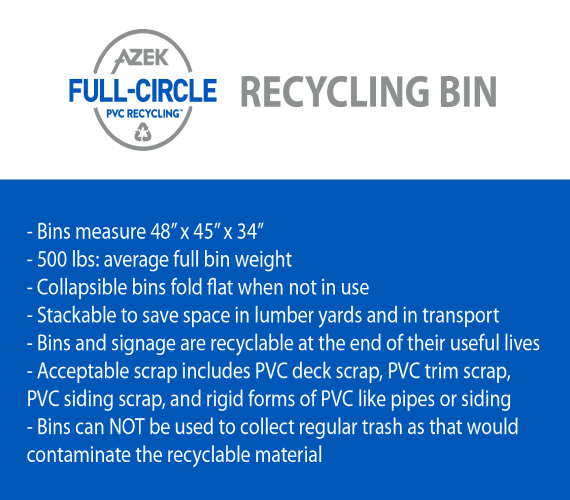

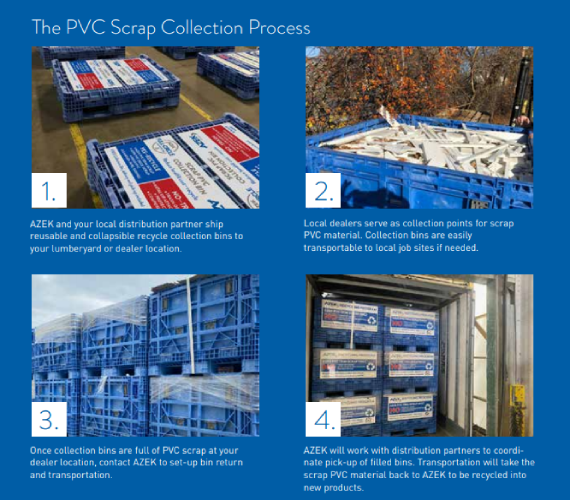

On the ground, collecting PVC scraps required partnering with AZEK’s strong network of distributors and contractors to participate and made it easy and efficient to drop off. So first, AZEK set up collection bins and established collection points along its value chain, including contractors, builders, dealers and distributors. Convenient, collapsible and storable 15-square-foot bins were delivered to AZEK’s participating distributors strategically located in popular PVC markets throughout the U.S., who then provided them to their key lumber yard customers for scrap collection. Lumber yards can either house the bins at their yard for contractors to collectively recycle their PVC scrap material or the bins can be provided to a contractor to fill them up on their jobsite. Once full, the lumber yard partner will pick up the bin from the jobsite and bring it back to their yard for pickup by the distributor. Once the distributor has aggregated enough bins for efficiency, AZEK will pick up and deliver the full bins to its PVC recycling facility in Ashland, OH.

“CCL is a strong supporter of the Azek recycling program for many reasons. Above all, it reduces the amount of waste that ends up in landfills. This has a positive impact on the planet, the environment and our local community. Our contractor customers love the recycling bins as well. When they have a job where they will be installing a large amount of Azek trim, we drop off a recycling bin at the jobsite. All their cutoffs and scraps go into that bin, and this reduces the amount of material that gets thrown into a dumpster. The less material that goes into the dumpster, the less they pay in disposal fees. We even use these recycling bins in our own custom millwork shop.”

– Cape Cod Lumber

Making takeback sensible

It’s a sustainable, full circle product lifecycle process that helps every participant in the supply chain either gain efficiency, valuable raw material and/or operational savings, and reduce their environmental impact. As for logistics, with AZEK already sending materials to its distributors, now the return journey can include bringing scrap PVC bins to Ashland to form a continuous loop. The PVC scraps are then processed to allow them to be used by AZEK’s plants for new products, including its TimberTech® AZEK®decking line made from approximately 50% recycled content. In 2020, AZEK used approximately 400 million pounds of recycled product, including primarily recycled polyethylene, recycled PVC and recycled wood flour. That was up from approximately 290 million pounds in 2019.

Ryan Manley, Business Development Manager, who joined AZEK in 2021 to help roll out FULL-CIRCLE™ with the company’s contractors and business partners, says the program is helping pave the way to a more efficient and sustainable future for their industry. “We’re working with our entire value chain. Our program helps contractors cut disposal costs and keeps PVC out of landfill. It’s a win-win,” he says. His hope: that this entire value chain approach can disrupt the plastic waste paradigm meaningfully as AZEK continues to scale up collection and processing en route to 2026.

Faster and first

The team is aware that doing things right isn’t enough. They must do it faster, more efficiently and first, given the fragmented and disparate supply chain and associated logistics. With the recycling industry starting to pick up momentum, Manley knows that first in class will require more than what they have accomplished thus far. “We’ve had some great early wins. We have generated a lot of excitement in seven short months since formally launching FULL-CIRCLE. We’re already shifting from outbound network building, marketing and relationship building to fielding incoming requests from distributors and lumber yards for our collection bins,” he says, adding, “They want in!”

In other words, to create goods that do good, AZEK must inspire its entire value chain to participate – and this is where, according to Manley, economics will eventually win the market. “Our products are aesthetically beautiful, natural-looking and help change the perception that recycled products are sub- quality or sub-par or plain ugly. And they help divert waste from landfill to create products with a lower carbon footprint that can last 50+ years and then can be reclaimed and recycled at the end of their life as well,” he says

Historically, recycled products have been viewed as inferior to virgin plastic and AZEK is positioning its products as just as good if not better. For the AZEK team, FULL-CIRCLE is clearly a company-wide mission with all hands on deck. “This is about the heartbeat of our organization. We’re working across business units and regions. We’re educating our supply chain and making it as easy as possible for them to participate,” offers Ryan. The fact is: there is limited infrastructure for recycling PVC in the United States and AZEK is innovating in the industry as they invest and expand the network. The greater the awareness, enthusiasm and operational savings, the more quickly FULL-CIRCLE™ will scale.

Put simply, a humble recycling program has today become a key aspect of AZEK’s business strategy. FULL-CIRCLE™ is ambitious, industry leading and potentially disruptive for the market if it continues to scale as the company expects it to. While the last seven months have been promising, Ryan knows the next six will be harder as the company expands its networks beyond the naturally sustainably-minded distribution partners. As AZEK heads out West to add more connection points along its value chain, the mood is one of optimism and excitement. Leadership takes courage and investments, and AZEK is all in.

About The AZEK Company Inc.

The AZEK Company Inc. (NYSE: AZEK) is the industry-leading designer and manufacturer of beautiful, low maintenance and environmentally sustainable outdoor living products, including TimberTech® decking and railing, Versatex® and AZEK® Trim, and StruXure® pergolas. Consistently awarded and recognized as the market leader in innovation, quality, aesthetics and sustainability, our products are made from up to 85% recycled material and primarily replace wood on the outside of homes, providing a long-lasting, eco-friendly, and stylish solution to consumers. Leveraging the talents of its approximately 2,000 employees and the strength of relationships across its value chain, The AZEK Company is committed to accelerating the use of recycled material in the manufacturing of its innovative products, keeping hundreds of millions of pounds of waste and scrap out of landfills each year, and revolutionizing the industry to create a more sustainable future. The AZEK Company has recently been named one of America’s Climate Leaders by USA Today, a Top Workplace by the Chicago Tribune and U.S. News and World Report, and a winner of the 2024 Real Leaders® Impact Awards. Headquartered in Chicago, Illinois, the company operates manufacturing and recycling facilities in Ohio, Pennsylvania, Idaho, Georgia, Nevada, New Jersey, Michigan and Minnesota.

Why +Vantage Vinyl™?

At AZEK, we are committed to innovating, inspiring, reinventing, revolutionizing and leading our industry to create a more sustainable future. The +Vantage Vinyl verification underscores and validates this commitment, while promoting environmental and social governance across the entire vinyl industry value chain.

Learn more about this company’s +Vantage Vinyl verification at ![]()

INTERESTED IN BECOMING +VANTAGE VINYL VERIFIED?

Take the first step toward earning + Vantage Vinyl verification by learning more here.